PALM ACID OIL (PAO)

Palm oil is extracted from the mesocarp of the fruit of an oil palm species called Elaeis guineensis. In Malaysia, the high yielding tenera, which is a cross between dura and pisifera species, is the most commonly cultivated palm tree.

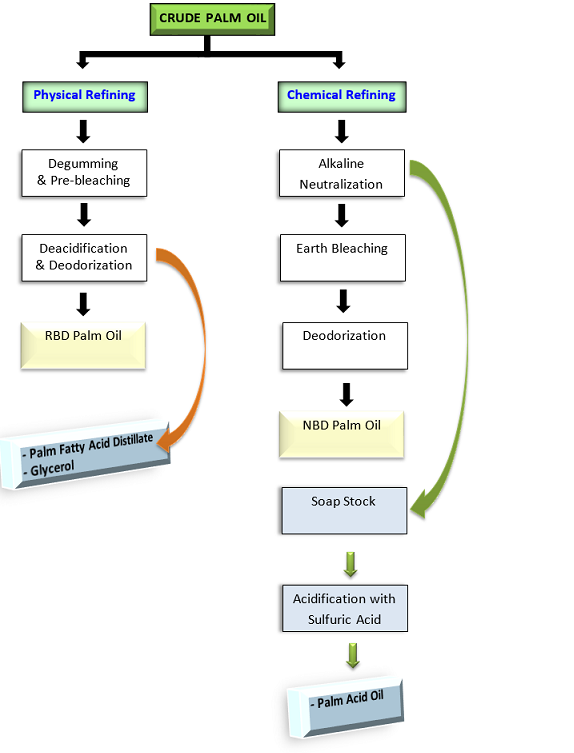

Crude palm oil obtained from the mesocarp of the palm fruit must be processed before it is used in edible applications. Processing involves refining, bleaching and deodorizing the oil. There are two types of refining, namely physical and alkaline/chemical refining.

- Physical refining involves steam distillation under vacuum (2-6 mm Hg) at 240-260o

- Alkaline refining involves neutralization with alkali such as caustic soda. One of the by-products of alkaline refining is soapstock, which contains some emulsified neutral oil. The soapstock is easily separated from the neutralized oil by density-difference or centrifugal separation. Acidification of the soapstock gives the acid oil. The main components of palm acid oil (PAO) are free fatty acids (FFA), neutral oil and moisture.

Palm Acid Oil (PAO) is a by-product from the chemical refining of palm oil. It consists mainly of FFA (over 50%) and neutral oil, with 2-3% moisture and other impurities. It is very similar to Palm Fatty Acid Distillate (PFAD), but its FFA is generally lower. Except for some special uses, the relative proportion of FFA to neutral oil does not usually matter very much, as it does not affect its fitness for use. In most cases the smell and colour are more important.

The main uses of PAO are in animal feeds, in soap making, biodiesel production, and for distilled fatty acid production. The properties and composition of PAO may differ according to variations in the palm oil feedstock and the alkaline refining process. This product is not now produced on any great scale because in Malaysia and Indonesia, the palm oil is refined by the physical process which produce PFAD rather than PAO.

Specification:-

| Total Fatty Matter | 95% min. (basic 97%) |

| Moisture & Impurities | 3.0% max. |

| * Free Fatty Acid (As Palmitic) | 50% min. |

| Colour | Yellow / Light brown |

*: Molecular Weight of Palmitic Acid is taken as 256

Packaging:-

- Used steel drum: 185kgs/drum x 98 drums per 20ft container [18.13 MTs]

- Flexibag in 20ft container: ±21 MTs per 20ft container

- Bulk vessel

PALM OIL REFINING PROCESS

PROCEDURES TO OPERATE THE HEATING PAD WHEN DISCHARGING LIQUID:

SHORTER TUBE – Inputting steam source [installed on the right door of container]

LONGER TUBE – Outputting the steam source [installed on the left door of container]

- Once laden container reached, open the right door of the container.

- Hand the outputting hose to the outside left door of the container.

- Straighten the hoses and check if they are not bent, kinked or twisted.

- Connect the inlet hoses to the steam or hot water hoses. Ensure that steam or hot water is properly discharging from the output hoses.

- Slowly increase steam or hot water pressure to the heating pad. Check the melting temperature of the product and ensure that the heat source is not hot to overheat the product.

- Once the product has been sufficiently melted, start to discharge the product. Do not turn off the heat source at this stage.

- Heating until one quarter of the product remains and slowly decrease the steam or hot water pressure. Pump out the remainder of the product.

- Allow the heating pad to be sufficiently cool before you disengage the hoses. Dispose the heating pad once the operation is over.